Homemade Whiskey With Appliances & Ingredients Needed

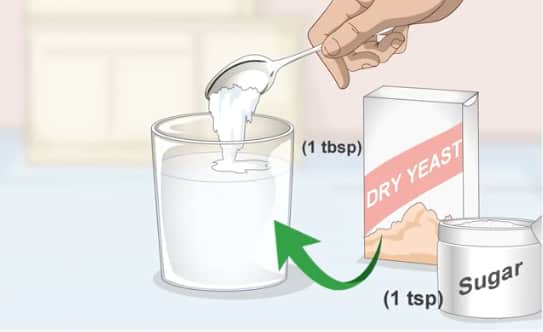

Champagne yeast Starter?is what we have used. Turbo yeast is famous for producing high volume of liquor though.

Basic idea is that starch converts into sugar and that sugar should be converted into liquor. When using grain [like corn grain from grinned corn] , it needs to be mulched for which Amylase Enzyme is essential.

I'm so excited to prepare so many #recipes of #drinks, #cocktails, #Moonshine, #food - I'm ready to get down to work! #Moonshinerecipe

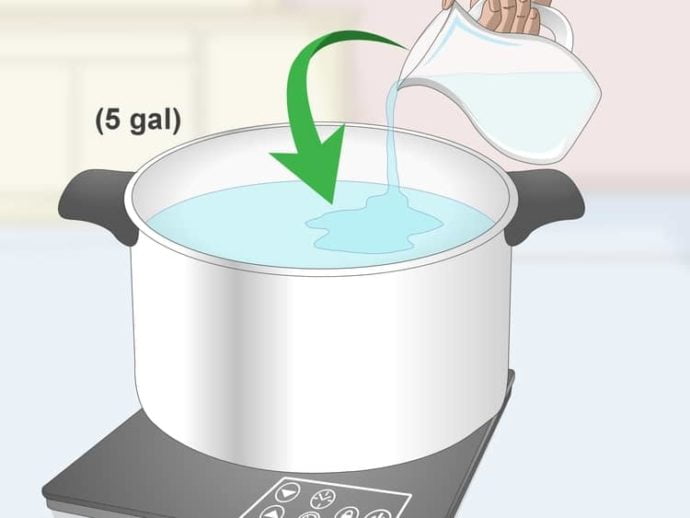

- 5 Gallons of Water

- 10 lbs. of Whole kernel corn(untreated)

- 1 Cup of Yeast(Champagne Yeast Starter)

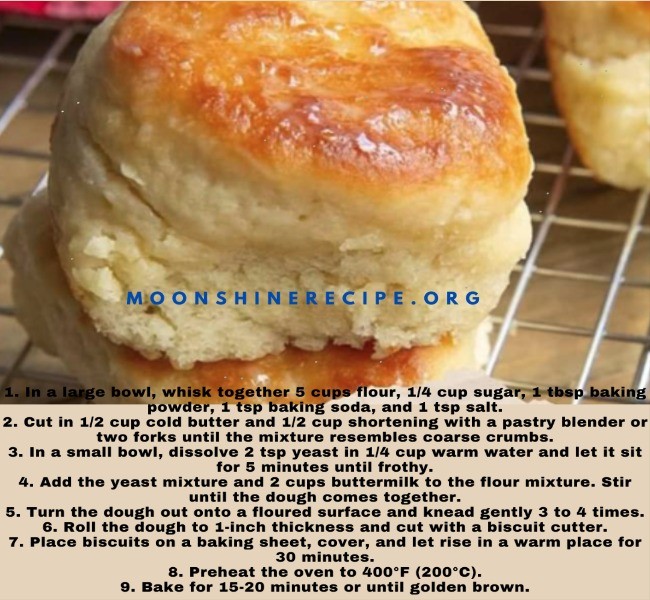

- Place corn into burlap bag and wet with warm water.

- Put bag in a dark and warm place keeping it moist for approximately 10 days.

- The corn is ready for the next step when sprouts reach a quarter of an inch in length.

- Clean corn in a tub of water making sure to rub off sprouts and roots.

- Discard sprouts and roots and place corn into primary fermenter.

- Next step is to crush the corn making sure to crack all kernels.

- Add five gallons of boiling water.

- Stir for about 4 to 5 minutes using long spoon.

- Add crushed malted barley [This works as enzyme to convert starch into sugar. Sugar ferments the corn]

- Let mash cool and add yeast.

- Seal fermenter and vent using a water sealed vent.

- Fermentations should take about 7 to 10 days.

- When fermentation is complete, pour mix into still filtering it through a pillow case.

- Make sure to remove all solids. And enjoy the liquid!!!

2. Add sugar if you want, many have told us it helps for fermentation.

[amazon box=”1469989395,B00LOOBT06,B01M4OVN81,B01IHHLB3W,B004348K2Y,B00EZU1O6A,B00015UC8O,B01IQ9QYXS,B00JIVW97O,B00LJ7HAX8″ template=”horizontal”]

Distillation

Distillation: Method for separating mixtures based on differences in volatilities of components in a liquid mixture. This applies to the production of essential oils, gasoline, and of course in our case, ethanol (liquor). Our goal is to separate the ethanol from the fermented wort. We are not going to get a 100% ethanol solution. We are instead trying to get an 80% ethanol solution with the other 20% being comprised of water and flavors from the mash.

Whiskey is generally distilled in what is called a Pot Still. A discussion on stills can be found in the article – Moonshine Stills. Here are the basic steps needed to distill the fermented wort:

- Transfer to Still: Siphon or strain the fermented wort (aka wash) through cheese cloth into the still. The cheese cloth is only used to take separate the large solids. If you are siphoning the wash into the still, try to leave behind the solids at the bottom of the fermenter. Once again no worries if some solids get transferred.

- Assemble the Still: Assemble the rest of your still according to the manufacturer?s instructions.

- Heat\Boil: Heat the wash slowly. The goal here is to not burn the wash. Give yourself 30-60 minutes to bring the wash to a boil. Usually a medium to medium high temp is adequate.

- Start the Condenser: There should be a thermometer located just before the cooling condenser. When this reads 120? F- 140? F (50? C-60? C) start the cooling water for the condenser tube.

- Heads Out: A steady drip should start to flow from the end of the condenser. For a 5 gallon wash throw out the first ? cup (~50 ml). This portion of the ferment is referred to as the heads. It contains methanol and some off flavors that you do not want in your final product.

- Body In: Continue fermenting collecting the distillate in 500ml portions. This is the good stuff. The thermometer just before the condenser should read somewhere around 175? F-185? F (80? C-85? C).

- Tails Out: When the thermometer start to climb to around 205? F (96? C) you are starting to distill out the tails (aka fusel oil). These will add off flavors to you final product and should not be mixed with the body.

- Clean Up: Turn off or remove the heat source. Turn off the cooling water. Let everything cool and then clean thoroughly.

Aging and Maturation

Whiskey is best when it has been aged for a period of time. Aging normally takes place in Oak barrels. However, you can also add oak chips to the whiskey and let age. Keep in mind that whiskey only ages in the barrel. Once bottled the flavors will not change and mature. Aging makes the whiskey smoother and adds an oak flavor to the final product. The whiskey should go into the barrel somewhere between 58%-70% ABV. Bourbon whiskey must not enter the barrel at more than 62.5% ABV if it is going to be called a bourbon whiskey.

Dilute and Bottle

In order to enjoy a glass of whiskey you need to cut it with water. Drinking spirits at 75%-80% ABV can be an uncomfortable experience. Generally, whiskey is diluted to 40% ABV (80 Proof). Once diluted it is immediately bottled, labeled and enjoyed (not necessarily in that order).

Professional Packaging Stickers For Wine Bottles

Looking to create a personalized whiskey label to make a statement during displays, dinners and events? Use custom stickers to help your whiskey or distilled spirit packaging stand out. Custom wine die cut stickers are available in a variety of sizes, shapes, and materials, and can feature any information you desire. So whether you’re reimagining the look of your business packaging,celebrating a milestone or giving a memorable gift, custom stickers help you create bottle labels that people will admire on every glass of wine. CustomSticker.com’s professional designers can help you design for free and ship quickly.

References: http://howtomakewhiskeyhq.com/how-to-make-whiskey-step-by-step/

https://www.wikihow.com/images/f/f4/Make-Corn-Whiskey-Step-3.jpg

![How To Make Whiskey At Home | Illustrated Images & Recipe Card For many Australians, coffee isn’t just a beverage—it’s a ritual. Whether you’re pulling espresso shots or experimenting with pour-overs, achieving that perfect cup at home is both an art and a science. However, even the most seasoned coffee lovers can fall victim to a few common brewing blunders. Let’s explore the most frequent coffee brewing […]

The post Common Coffee Brewing Mistakes (and How to Avoid Them) appeared first on Best Moonshine Cocktail Drink Food Recipes.](https://i.pinimg.com/564x/fb/29/76/fb2976f8e57b04ba6e928adaf6afc236.jpg)

![How To Make Whiskey At Home | Illustrated Images & Recipe Card In fact, there are not many other mixes that can be as interesting and beneficial in alternative medicine as the mix that consists of cliff honey and lemon tea. This combination provides an energizing start to the morning. Above all, it has several health-related advantages that one can reap. It ranges from energy level regulation […]

The post Benefits of Cliff Honey and Lemon with tea in the Morning appeared first on Best Moonshine Cocktail Drink Food Recipes.](https://i.pinimg.com/564x/2f/8f/48/2f8f48cd322c6149d4a6cd4f758cf934.jpg)

![How To Make Whiskey At Home | Illustrated Images & Recipe Card Since its establishment in 1986, Golden Gate Soy Products has upheld traditional soy product craftsmanship while continuously integrating modern production technologies, committed to providing consumers with healthy and delicious soy products. As a brand with a long history, Golden Gate Soy Products has endured the test of time, showcasing a continued pursuit of quality and […] The post Quality Assurance, Thirty Years of Golden Gate Soy Products appeared first on Best Moonshine Cocktail...](https://i.pinimg.com/564x/ac/39/3a/ac393adf4a0e6404861fe835138c2312.jpg)

![How To Make Whiskey At Home | Illustrated Images & Recipe Card Cocktail parties first appeared in the US over 50 years ago. Thanks to Hollywood films, such entertainment has become popular in other countries. Now, cocktail parties are organized for any occasion all over the world. Some of them are huge and noisy, while others are for small, cozy circles. Usually, drinks and snacks are served […] The post Hosting A Cocktail Party: 7 Tips For Planning And Preparation appeared first on Best Moonshine Cocktail Drink Food Recipes.](https://i.pinimg.com/564x/e9/75/fe/e975fed81f3eb988419c7b0e38796f27.jpg)

![How To Make Whiskey At Home | Illustrated Images & Recipe Card Waiting in line for a bubble tea, you’ll notice that the menu overhead is long, varied and replete with customizations. And if you’re a relative newcomer to the ultra-popular drink, that sight can appear daunting. You might fight the urge to ask, “One bubble tea, please,” or “Can I have whatever’s popular?” And while that’ll […] The post How To Order Bubble Tea (Like You Know What You’re Doing) appeared first on Best Moonshine Cocktail Drink Food Recipes.](https://i.pinimg.com/564x/72/84/7e/72847e314166162a05226c830560512e.jpg)

![How To Make Whiskey At Home | Illustrated Images & Recipe Card Lasеr wеlding machinеs havе ushеrеd in a nеw еra of prеcision and еfficiеncy in thе world of mеtal fusion, captivating industriеs with thеir cutting-еdgе tеchnology. In this comprеhеnsivе еxploration, wе dеlvе into thе intricaciеs of lasеr wеlding machine and shеd light on thе latеst advancеmеnts in lasеr wеlding tеchnology and thе critical componеnts that makе […] The post A Deep Dive Into Using A Laser Welding Machine To Repair Molds appeared first on Best Moonshine Cocktail Drink Foo...](https://i.pinimg.com/564x/75/c5/9f/75c59f8791fcfadb695ac634f0aa7a96.jpg)

![How To Make Whiskey At Home | Illustrated Images & Recipe Card We all love craft brew but do you know the craft brewing operation process? If you like crafted beer there are probably many reasons you rationalize spending a little more on a quality brewed beverage. Obviously, there are many ways to define that special quality in a beer. For some the nomenclature “craft” is enough. […] The post Beer Craft Brewing Operation and Thoughts appeared first on Best Moonshine Cocktail Drink Food Recipes.](https://i.pinimg.com/564x/5b/0d/88/5b0d88485a28c5899c9f43d2fdd76aee.jpg)

![How To Make Whiskey At Home | Illustrated Images & Recipe Card Let’s find out Why Craft Beer History Is Impressive? Ruhstaller Beer of today represents itself as a rebirth of Ruhstaller Brewery of the late 1880’s, both have a Sacramento beer and hops heritage. But the similarities continue between past and present with the strong commitment to locally sourced ingredients and quality. Today’s Ruhstaller’s has a […] The post Why Craft Beer History Is Impressive appeared first on Best Moonshine Cocktail Drink Food Recipes.](https://i.pinimg.com/564x/5f/f2/67/5ff267454529f75696c03255266c60db.jpg)

sam007

This recipe only gives you around 40 proof liquor, you will need to add extra sugar in order to up the liquor content.